Warehouse safety is one of the biggest challenges faced by warehouse managers and their employees.

With workers routinely handling heavy materials, hazardous substances, and complex machinery, optimising safety in this high-risk environment becomes crucial to your overall mining operations.

With a number of unique safety challenges faced by warehouses in mining operations, innovative workplace solutions are required to safeguard warehouse employees and reduce the incidence of work-related deaths, injuries and illnesses.

Backsafe Australia is a leading provider of materials handling and storage solutions, with over 20 years of experience in industries such as mining, warehousing, and remote facilities. Renowned for our human-centred engineering approach, which focuses on improving workplace safety, efficiency, and productivity, we're the trusted team for global mining giants, including BHP and Rio Tinto. Offering a wide range of tailored solutions, Backsafe is committed to helping mining warehouses optimize their safety protocols while enhancing operational efficiency.

In this article, we explore some of the main health and safety issues faced in the warehousing industry, discuss some of the key safety equipment and provide some helpful warehouse safety tips you can implement to optimise your operations.

The Unique Safety Challenges in Mining Warehouses

Due to the nature of the materials they store and the environments in which they operate, mining warehouses face a unique set of occupational safety challenges. With heavy materials, such as mining equipment, machinery parts, and raw minerals, all too common, manual handling becomes particularly hazardous.

Safe storage of things like chemicals and fuels is also a crucial aspect of warehouse safety, with specialised storage solutions needed to prevent accidents, spills, or contamination- all while adhering to the industry's strict fire safety standards.

The location of mining warehouses also impacts safety, with harsh environments and extreme weather conditions increasing the risk of accidents. Dust, moisture, and temperature fluctuations can affect the structural integrity of storage systems and equipment, posing further risks to workers, which makes proper safety training critical to preventing incidents. Ergonomically designed equipment is key to reducing the risk of musculoskeletal injuries while managing slip and trip hazards is essential to minimising accidents in these demanding environments.

Some of the main safety challenges faced in mining warehouses include:

Manual handling of heavy materials

Workers often handle large and heavy machinery parts, raw materials, and equipment, increasing the risk of musculoskeletal injuries.

Hazardous substances

Specialised storage solutions are required for chemicals, fuels, and lubricants that are prone to spills, leaks, and contamination.

Slip, trip, and fall hazards

Uneven surfaces, cluttered walkways, and improperly stored materials can lead to slips, trips, and falls, one of the most common causes of workplace injuries.

Fire safety risks

Flamable substances and the presence of combustible materials in harsh environments heighten the risk of fire hazards, making strict fire safety protocols essential.

Poor ergonomics

Inadequate equipment design or improper lifting techniques can lead to strains and injuries, especially in repetitive tasks.

Extreme environmental conditions

Mining warehouses are often exposed to extreme temperatures, moisture, and dust, which can degrade equipment and storage systems, creating safety risks.

Lack of proper training

Insufficient training in safe handling practices and equipment use can lead to accidents and injuries, emphasising the need for ongoing education and compliance with safety procedures.

Personal protective equipment (PPE) compliance

Ensuring that workers consistently use appropriate PPE, such as helmets, gloves, safety goggles, and steel-toe boots, is essential for preventing injuries. Failing to enforce proper PPE use increases the risk of injury from falling objects, chemical exposure, and other workplace hazards.

Safe Storage Solutions for Mining Warehouses

Safe storage is a key element in maintaining and optimising safety standards within your mining warehouse.

Proper storage not only minimises the risk of accidents but also enhances workflow efficiency by keeping the workspace organised and accessible. When materials are stored haphazardly or without the proper containment, they can easily become potential safety hazards—falling objects, obstructed walkways, and unsafe stacking are common causes of injuries.

Backcsafe Australia leads the way with innovative storage systems that can vastly improve warehouse safety. Our tailored storage solutions help mitigate these risks by providing robust, secure containment systems that prevent materials from shifting, falling, or causing blockages in the workspace - all while ensuring proper ergonomics.

Choose from a variety of storage systems, all designed to ensure the secure containment of materials, including hazardous substances. Our heavy-duty shelving, pallet racking, and custom cabinets offer durable, organised storage options that can withstand the demanding conditions of mining environments and ensure safety equipment is stored correctly.

The safe storage of hazardous substances is another key challenge for warehouse managers. But it doesn't have to be. Backsafe’s chemical storage cabinets, spill containment units, and gas cylinder cages are designed to comply with Australian safety standards, ensuring that hazardous materials are stored safely and securely. These solutions reduce the risk of spills, leaks, and contamination, protecting both workers and the environment.

For more resources on workplace safety, visit our Safe Work Information section.

Manual Handling Best Practices for Mining Warehouses

Manual handling is one of the most common sources of injury in mining warehouses. Lifting, carrying, and moving heavy materials without the proper equipment can lead to serious injuries, including back strain, muscle tears, and even long-term musculoskeletal disorders. To protect your workers and increase your overall operational efficiency, it's crucial to implement best practices in manual handling.

Backsafe Australia offers a range of manual and electric handling equipment that helps workers move materials safely and efficiently. Our custom handling solutions, including manual trolleys, pallet jacks, and electric lifters, are designed to reduce the physical strain on workers while increasing productivity.

Take our compact electric pallet jack, for example. The jack enables you to move heavy loads with minimal effort, significantly reducing the risk of injury associated with lifting or pushing. The simplified design provides everything you need and nothing you don’t: easy operation, robust construction, and powerful performance.

While the right equipment is crucial, it's equally important to train workers on safe manual handling techniques, such as proper lifting posture, load assessment, and the use of mechanical aids. Backsafe provides the equipment and expert advice on implementing safe manual handling practices that align with workplace health and safety (WHS) guidelines.

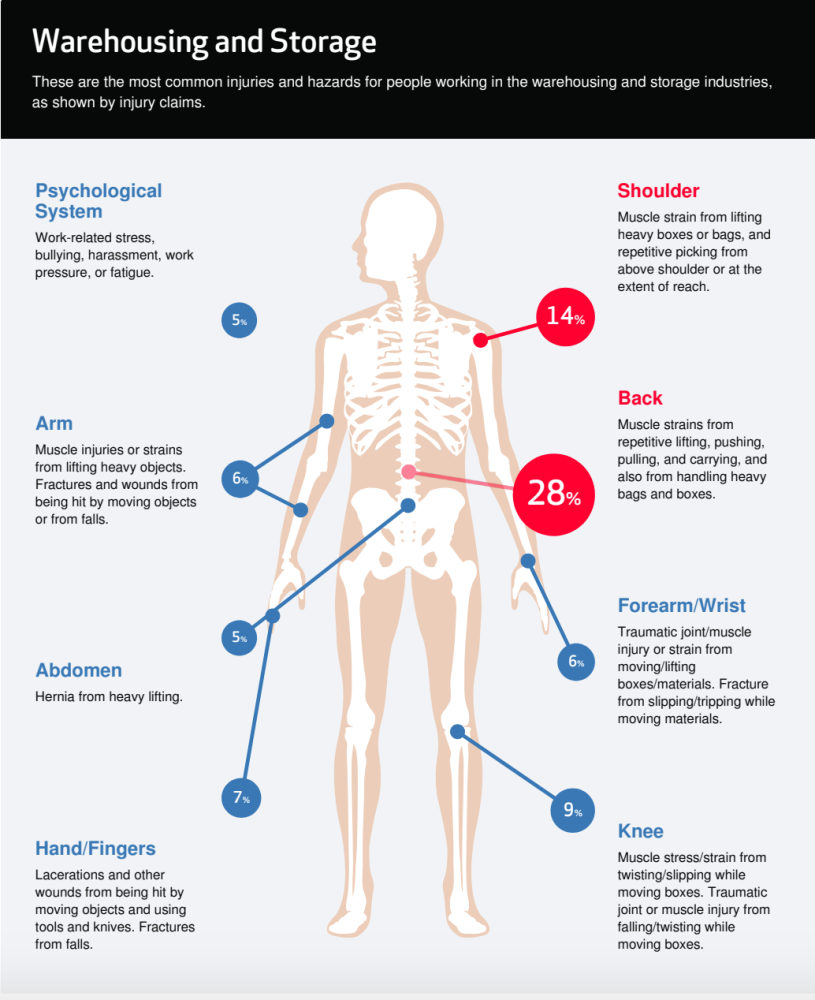

Learn more about warehousing and storage injury hotspots.

Warehousing and storage injury hotspots

How Backsafe Australia Enhances WHS

Backsafe Australia is committed to improving workplace health and safety (WHS) through our innovative, human-centred engineering approach, addressing the safety risks inherent in mining operations. Our products are designed with ergonomics in mind, ensuring that workers can handle materials safely while minimising physical strain. Our focus on the risks involved in manual handling goes beyond just product design, working closely with clients to develop tailored solutions that meet the specific needs of each operation.

Improving safety doesn't have to come at the cost of efficiency with innovative solutions that optimise your operations and boost your productivity. For example, by introducing automated or electric handling equipment, you can reduce the physical demands on your workers, lowering injury rates and minimising downtime due to accidents. At the same time, these solutions streamline your workflows, enabling faster and more efficient material handling, which leads to improved operational performance.

We take safety very seriously, ensuring we adhere to the highest safety standards in product design and functionality. All of our solutions are developed in compliance with Australian regulations, ensuring that warehouse operators can trust their equipment to meet the rigorous demands of mining.

Avoiding Common Warehouse Safety Hazards

Investing in the right equipment is essential for optimising warehouse safety in mining operations.

By addressing the unique challenges faced by mining warehouses, Backsafe Australia’s tailored storage and manual handling solutions ensure that workers remain safe while optimising efficiency and productivity.

With our commitment to WHS and expertise in human-centred engineering, we're the ideal partner for mining warehouses looking to improve safety and efficiency. Whether you need custom storage solutions, manual handling equipment, or expert advice on workplace safety, Backsafe offers proven solutions to improve your business on every level.

If you’re a mining warehouse operator looking to enhance safety and efficiency, contact Backsafe Australia today for a no-obligation consultation. Our team of experts is ready to help you identify your safety challenges and explore customised storage and handling solutions that align with your WHS goals.

Let us help you optimize your warehouse operations for a safer, more productive future.